Effective wood shredding with Ecopolymer shredders

Wood waste processing is very popular nowadays. Wood is a valuable raw material that can be used until the last chip. After processing, it can be used to obtain energy in heating boilers or for the production of fuel briquettes.

The first Ecopolymer shredders of the 2010s were used specifically for wood processing. Since then, a lot has changed for the better, from a technical point of view. We are constantly improving our production technologies and implementing modern solutions.

During our work, we have manufactured and installed a significant number of wood shredders in Ukraine and Europe. Thanks to this, we have accumulated a lot of experience in the development of this equipment. We can implement for you an individual solution of different power and productivity.

Our shredders effectively handle the shredding of wood of various species and in the form of various wastes (pallets, old furniture, window frames, scraps from the carpentry industry, logs, etc.).

Our equipment is successfully used both at processing enterprises and at production enterprises – to promote waste-free production.

- Samples of wood waste

- 1) What do we offer for processing enterprises?

- 2) What do we offer for manufacturing enterprises?

- Examples of using Ecopolymer shredders for wood shredding

- Possibility of remote testing of our equipment

“Given the intensive deforestation in the world, wood recycling concepts are especially necessary. And shredding is at the heart of these processes.”

Samples of wood waste

1) What do we offer for processing enterprises?

Shredders for wood processing

Wood processing into heating briquettes

Anyone who wants to generate energy from wood waste is thinking about shredding it. Remains of wood, chopped into chips, can be immediately used to obtain heat by burning. Or use to produce more efficient fuel briquettes, such as RUF, Pini Kay, Nestro…

Ecopolymer rotary shredders play a key role in this process, helping to shred wood into different fractions.

Processing of various types of wood waste

We provide recycling of all types of hard and soft wood, lumber, OSB and MDF waste, veneer, plywood, doors, furniture and pallets.

Don’t worry about nails and screws – when processed on a shredder, they are simply shredded together with the wood, and then they can be easily separated using a magnet.

Utilization and wood processing from Ecopolymer

Using a crusher or shredder from Ecopolymer, you will grind everything down to the last chip and dispose of wood waste in the most ecological way. Depending on your task, we offer different types of shredders.

For pre-shredding, the Shark EZ40 twin-shaft shredder is available, which is used for large waste wood such as pallets, window frames or furniture.

For smaller pieces of wood, with our versatile Shark ES series shredders, you can achieve the highest performance.

For the smallest material sizes, we offer shredders of the ENZ series.

Various options for the disposal of wood waste:

- Wood chips can be burned immediately in furnaces

- Biogas can be produced from wood chips (wood gasification installations in biothermal power plants)

- Chopped wood can be compressed into briquettes

- Wooden briquettes can be sold

- Wood waste can be processed into chipboard

Comprehensive solutions for wood processing: grinding, transportation, pressing

Thanks to our extensive experience with shredders and conveyor technologies (pneumatic conveying, screw conveyors, hopper systems, conveyor belts, metal detection and separation), we can offer you a complete package of solutions for a task such as wood processing from a single source. You will receive optimal equipment for your own energy production.

2) What do we offer for manufacturing enterprises?

Internal wood processing at the enterprise, as part of the strategy of zero-waste production

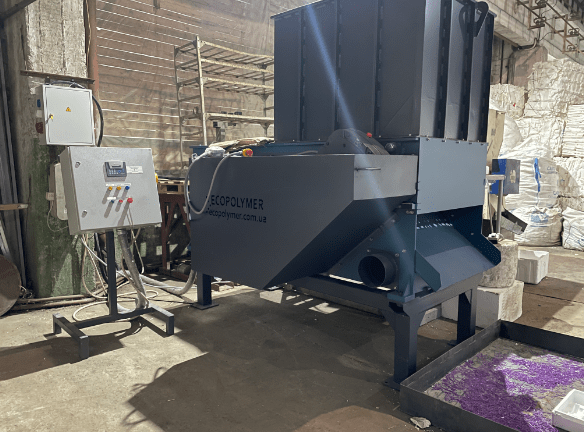

Every woodworking enterprise will benefit from the Shark ES series shredder

Wood processing has always been relevant and is unlikely to change in the future. All carpentry, carpentry, sawmill and furniture workshops inevitably generate wood waste during production. They must be disposed of or made suitable for further use. Therefore, companies are looking for more and more effective solutions in this direction. Ecopolymer shredders are modern and powerful equipment aimed at solving exactly this problem.

Inevitable accumulation of wood waste

Whether you use a planer or drill, circular saw, sander or lathe, woodworking produces a lot of wood shavings, sanding dust and sawing waste. Even CNC machines are no exception.

Use of wood waste for heating industrial premises

Wood waste generated during production is becoming more and more valuable. As secondary raw materials, they can be used for the production of heating briquettes: RUF, Pini Kay, Nestro… Briquettes, in turn, help to heat production premises.

The first step in this process is to chop the wood. Ecopolymer works closely with manufacturing customers to find the right solution for shredding different types of wood right at their plants. We use the accumulated experience to select the optimal configuration of the equipment, so that even those rocks that are difficult to process are qualitatively crushed.

Shredding of pallets

One of the most common applications of wood chipping is pallet chipping. Ecopolymer offers equipment specially designed for this task.

Processing of wood and pallets on our shredders is fast and reliable. In addition, we have developed a special crusher for pallets.

Why is a uniform particle size necessary when shredding wood waste?

Wood processing is a responsible process. Uniform particle size is particularly important in thermal disposal, as heating plants are often designed for a standardized particle size.

If their size is not uniform enough, heating systems using screw conveyors can quickly clog or fail. The formation of material bridges also prevents the smooth operation of the system.

In addition, the safety of the combustion system can be compromised if too large or long chips are used, which can block safety devices such as the rotary feed device.

For the production of high-density fuel briquettes, homogeneous shavings are also necessary. This is the only way fuel briquettes can stably keep their shape without binders and glue.

Examples of using Ecopolymer shredders for wood shredding

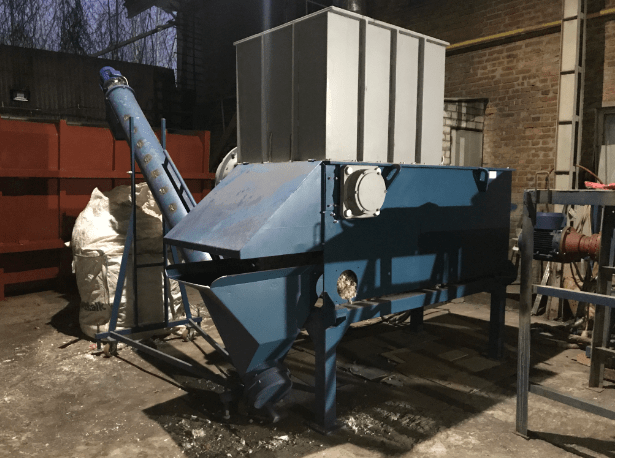

Pre-shredding of wood with an EZ20 shredder

Ecopolymer Shark EZ20 and EZ40 two-wave shredders are very powerful and designed for pre-shredding. They easily grind even very hard wood and large products from it. After passing through the shredder, it can be processed into shavings and compressed into heating briquettes.

Steady wood shredding

In the video, the Ecopolymer Shark ES 10.2 rotary shredder quickly shreds plywood waste.

Wood processing by shredding on a Shark ES13.2 shredder

The video demonstrates fast and high-quality grinding of solid pieces of wood. It can be waste from the carpentry industry, frames, doors, parquet, etc.

Novelty! Pallet crusher

Our product line includes equipment designed specifically for the processing of wooden pallets – a crusher for pallets. It helps to quickly and easily crush pallets into small fractions.

Wood processing by shredding on a Shark ES6.1 shredder

This small and powerful shredder can be successfully used to stably shred wood into chips of the required fraction.

Wood processing by shredding on a Shark ES10.2 shredder

This universal shredder is suitable not only for industrial shredding of wood, but also plastic, rubber and other types of waste.

Processing of wood of various types with Ecopolymer shredders

A short video demonstrates the shredding of various types of wood waste by Ecopolymer shredders.

Possibility of remote testing of our equipment

See for yourself!

You can send us your material for shredding. This will help you to quickly see the result that you will get, as well as to evaluate the performance of our equipment.

There is an opportunity to watch the processing process live, through a video recording or online broadcast.

Interested in equipment?

Contact us!

I will be happy to answer your questions and provide a consultation.